Graphite used in the field of machinery, chemicals and water treatment

Graphite lining

Product description

1. High temperature: graphite melting point of 3850 ± 50℃, boiling point of 4250℃, even after ultra-high arc temperature burning, the weight loss is small, the thermal expansion coefficient is small. Graphite strength increases with temperature and its strength doubles at 2000 ℃.

2. The electrical conductivity and thermal conductivity: graphite conductivity is 100 times higher than average non-metallic minerals. Thermal conductivity is higher than steel, iron and lead etc. Thermal conductivity decreases with increasing temperature, even at very high temperatures, graphite can become heat insulator. Graphite can conduct electricity because each carbon atom can only form three covalent bonds with other carbon atoms, each carbon atom still retains one free electron to transport charge.

3. Lubrication: lubrication performance depends on the size of the graphite flake, the greater the scale, the smaller the coefficient of friction and the better the lubrication performance.

4. Chemical stability: graphite has good chemical stability and corrosion resistance to acid, alkali and organic solvents.

5. Thermal shock resistance: graphite used at room temperature can withstand dramatic changes in temperature without damage. When there is sudden change in temperature, there will be only little change in the volume of graphite but will not crack.

Graphite lining has good electrical conductivity properties and corrosion resistance to high temperature, acid and alkali and ease of processing.

Application: widely used in metallurgical, chemical, electrochemical and other industries

Specifications: according to customer requirements on size and use environment

Packing: wooden box or wooden cage + pallet

Graphite bearing

Product description

Bearing is commonly used as a sliding material in the machinery industry. There are differences based on materials: metal parts, non-metallic and composite material. Graphite bearings are carbonaceous bearings which are devolved with the performance requirements of the machinery and equipment, based on the development of metal bearings, graphite materials as the main substrate. Unlike metal bearing, graphite bearing features mainly in: self-lubricating, resistance to high temperature and corrosion as well as light in weight and so on.

Graphite bearing has excellent characteristics:

1.Good self-lubricating properties: Because of its layered crystal structure, graphite has self-lubricating properties, suitable for use in high temperature environment, as well as areas of inappropriate use of liquid lubricant. Especially in the absence of lubricant when compared to other materials, it has properties of low coefficient of friction and difficult for adhesion.

2.Good chemical resistance properties to erosion of acid, alkali and inorganic chemicals.

3.Good heat resistance properties: Mechanical strength and sliding properties will not change due to heat.

4.Excellent thermal shock resistance properties: Compared to metallic materials, graphite has low thermal expansion coefficient and good thermal conductivity, will not crack even if rapid temperature changes.

5.Pro-light design: Compared to metallic materials, graphite has small bulk density which is good for weight reduction and reducing sliding mechanical noise.

6.Broadening product utilities: According to customer demand for a specific use of the environment, deep processing of graphite bearing can increase resistance to wear, high temperature and corrosion in different environments.

Application:presently used in conveyor bearings, pump bearings, submersible pump bearings, gears and bearings of food, beverage, textile, printing and dyeing, chemical and other industries as well as automobile, aerospace, agricultural machinery, etc. if grease lubricant is used in these parts, it will inevitably cause contamination. On the contrary, graphite bearing has strong self-lubricating function, which may be used for long-term operation without lubricants.

Specifications:according to customer requirements on size and use environment

Packing:wooden box or wooden cage + pallet

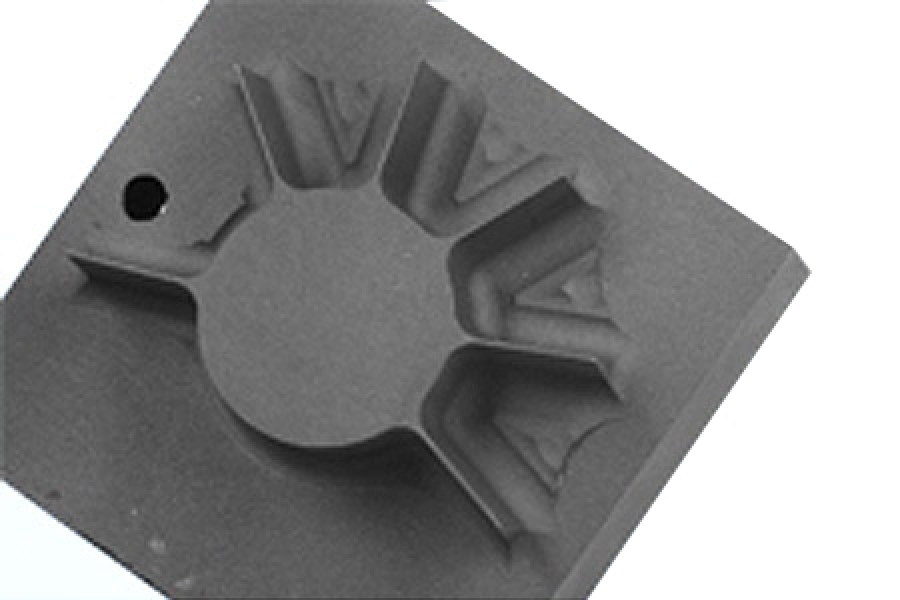

EDM graphite electrode

Product description

As widely used industrial technology in mold processing field, EDM has always played an important role. In order to ensure the quality of molds during EDM, electrode selection is critical. In the situation that energy-saving and high-efficiency become the hot topic in manufacturing industry, more and more customers choose graphite to replace traditional copper for electrical discharge machining (EDM). Facts have proved that the graphite electrode has excellent properties that copper electrodes do not have so as to improve the market competitiveness of enterprises and products, improve production efficiency resulting in cost reduction and profit increase. Persistent EDM electrode mold has high cutting speed and good performance.

Main features:

1.light in weight (one-fifth of copper) to reduce the EDM load

2.high speed electrical discharge machining (1.5 to 3 times that of copper)

3.high density, low wear rate

4.Low coefficient of thermal expansion (coefficient of thermal expansion is a quarter of copper), the situation means that thermal deformation is reduced, the products are produced higher accuracy.

5.Many different brands to choose from roughing, finishing to final precision machining

Applications:Widely used in EDM field

Specifications:according to customer requirements on size and use environment

Packing:wooden box or wooden cage + pallet

Graphite blade

Main technical data:

| Density (≥g/cm3) |

Hardness (≥) |

Air hole of opening (≤%) |

strength for pressure (≥Mpa) |

strength for bending (≥Mpa) |

Temperature for use (≤℃) |

| 1.65 | 60(HS) | 2 | 125 | 51 | 200 |

| 1.8 | 36(HS) | 3 | 52 | 22 | 200 |

| 1.9 | 50(HS) | 18 | 86 | 42 | 400 |

| 1.92 | 50(HS) | 2 | 88 | 42 | 200 |

| 1.74 | 105(HR) | 1 | 150 | 75 | 180 |

| 1.85 | 90(HR) | 10 | 150 | 58 | 600 |

Applications:all kinds of dry running compressor impeller, oxygen machines, vacuum pumps, compressors, dispensers, and printing and packaging equipments

Specifications:according to customer requirements on size and use environment

Packing:wooden box or wooden cage + pallet

Graphite ring

Product description

Carbon graphite ring has good properties of, self-lubricating, low friction coefficient, resistance to heat, abrasion, chemical and corrosion, good thermal conductivity, thermal expansion coefficient, high and low temperature performance and adaptability as well as materials physical and mechanical properties, and has been used as a key component of mechanical seal for hundreds of years.

Carbon graphite annulus are divided into many species, and are widely used in various compressors, turbines, reciprocating pumps and other mechanical equipments. According to the intended use, carbon graphite split ring can be divided into: piston rings, guide ring, filler ring, labyrinth seal, turbine, the turbine ring and compressed carbon graphite mechanical seal.

Our company will further enhance the deep processing of graphite ring product anti-oxidation, wear, corrosion resistance and other characteristics according to the customer requirement for specific environment and temperature.

Application:papermaking, textile, printing and dyeing, chemical fiber, rubber, plastics, chemical, pharmaceutical, food, cigarettes, packaging, printing, machinery, electrical appliances, building materials, metallurgy, steel, oil refining, military and other industrial sectors.

Specifications: according to customer requirements on size and use environment

Packingwooden box or wooden cage + pallet

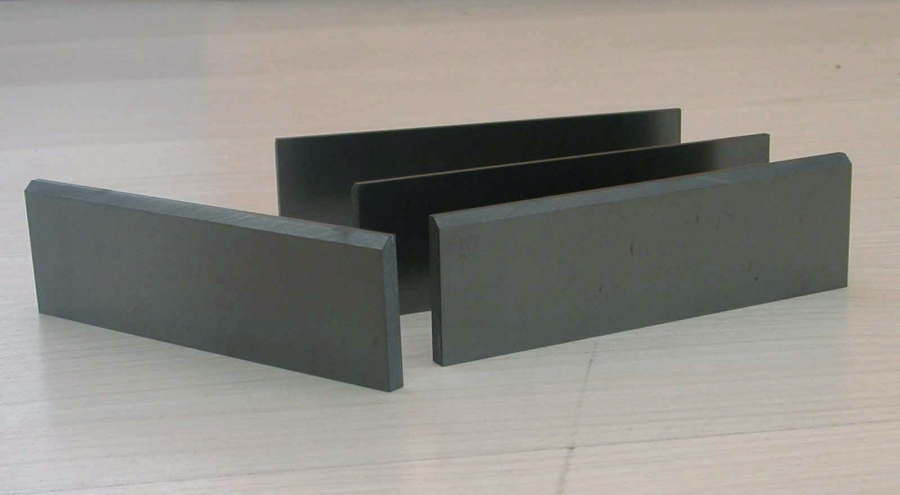

Graphite strip and graphite rail

Product description

Graphite strip uses high quality graphite as raw materials and is produced by a special processing technology.

1. Strong self-lubricating properties: Under conditions of without any lubricant, it can friction with a variety of metals with friction coefficient lower than 0.045 or less thereby increasing the life of the product.

2. Good thermal shock resistance: For temperature mutation, product itself will not get deformed, broken or inflated.

3. Corrosion resistance: It will not produce chemical reactions to most acids, alkalis and salt liquid.

4. High-temperature resistance: normal environment temperature of 450 degrees, 1600 degrees temperature under oxygen-free environment.

At present our company has established long-term stable relations with large medium-sized domestic and foreign brand stereotypes manufacturers for cooperation to explore and study the use of the graphite in the industry, and constantly improve the production process to provide better products for joint customers.

Applications:printing machinery, shaping machinery, food machinery, machinery and all kinds of non-oil pipeline equipments

Specifications:Regular size 9 * 13 * 1000, 9 * 13 * 500 and 9 * 13 * 200, or according to customer requirements for production of various shapes and sizes of graphite strip

Packing:wooden box or wooden cage + pallet

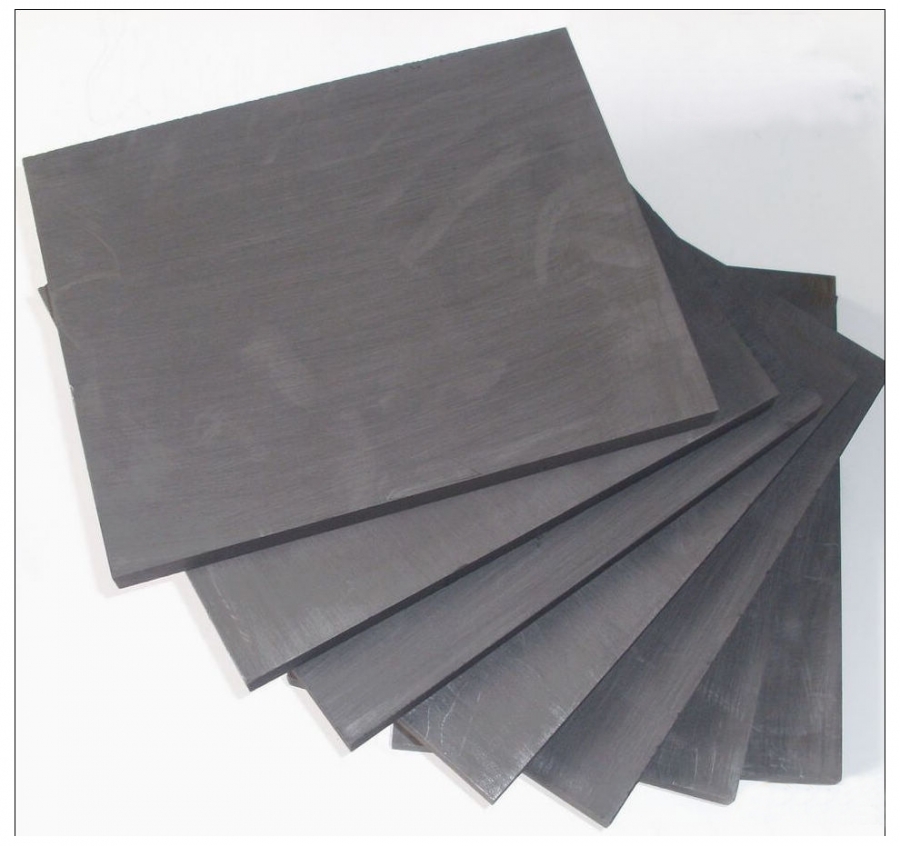

Graphite anode plate

Compared with other materials graphite anode plate has features of high temperature resistance, good thermal conductivity properties, easily machining, good chemical stability, acid and alkali resistance, and low ash, etc. and is often used as a conductive anode in the electrolytic solution, making chlorine, caustic soda, salt electrolysis solution for making alkali. Graphite anode plate can also be used as a conductive anode in electroplating industry and is an ideal material for a variety of electroplating. With graphite anode plates, the plating products are smooth, delicate, resistant wear and corrosion, high brightness, easy to change color. Top-Carbon graphite anode plate selects high quality raw materials of very low ash and excellent conductive properties and through computer-controlled ingredients, using 2500 tons press repression, the products are featured with low ash content, particle uniformity, conductive properties and flexural strength.

| parameters | Grade A | Grade B |

| Resistivity (μΩ.m) | ≤7.8 | ≤8.5 |

| Ash content(%) | ≤0.3 | ≤0.3 |

| Particle size (mm) | ≤0.8 | ≤2 |

| Compressive strength(Mpa) | ≥21 | ≥20 |

| Density (g/cm3) | ≥1.72 | ≥1.72 |

Applications:electronics, metallurgy, chemical, steel, environmental protection, sewage treatment and other industries

Specifications:according to customer requirements on size and use environment

Packing:Packing: wooden box or wooden cage + pallet

Small size graphite electrodes

Product description

Top-carbon unique small size graphite electrodes and carbon rod are specially designed for SMEs, with diameter of 8 to 175mm, length of 100 to 1600mm, with price competitive advantages due to mass production, and are widely used in mining thermal, metallurgical and chemical industries.

Small size graphite electrode is of excellent indicators of quality, complete specifications and in full compliance with customer requirements.

Applications:thermal mineral, metallurgical and chemical industries

Specifications:according to customer requirements on size and use environment

Packing:wooden box or wooden cage + pallet